Composites Manufacturing

Formtech Composites are well equipped for both Prototype Composites Manufacturing – suitable for demonstrators and proof of concept, but also for Small Volume and Serial Production of composite structures. Small volume manufacturing is usually the best approach for the motorsports sector, where designs might be updated several times through the season.

The Manufacturing Process

- 1. Detailed Drawings

- 2. Productionisation

- 3. Template Creation

- 4. Kit Cutting

- 5. Process Control

- 6. Laminating

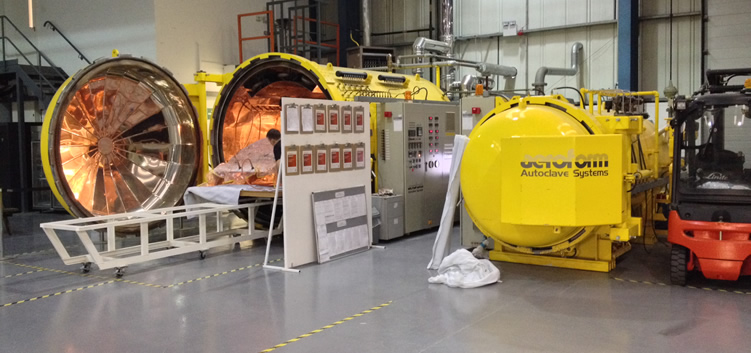

- 7. Curing

- 8. Quality

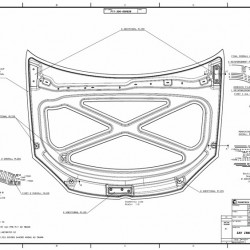

- Detailed Drawing: Detailed design specifications for part manufacture provided from FEA / Concepts.

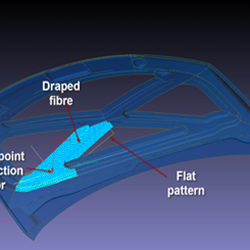

- Productionisation: Draping analysis create laminate definitions for manufacturing using Anaglyph “Laminate Tools”.

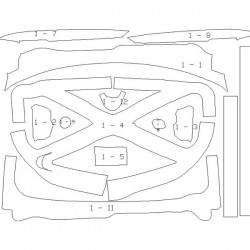

- Template Creation: In order to automate the kit cutting of material it is necessary to take the draped plies and unfold them to create a nested kit to cut.

- Kit Cutting: All kit definitions are passed to the 2D kit cutting machine to cut material for subsequent laminating. Kits are then stored for manufacture.

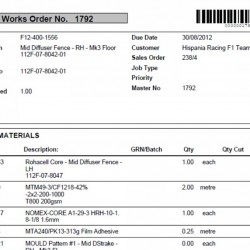

- Process Control: All aspects of a project are controlled by internal quality management / production system. Works orders are the controlling documentation for all processes and a record of quality.

- Laminating: Components are laminated in a Clean Room environment, Augmented Reality systems are used to control work processes.

- Curing: Fully Traceable Autoclave and Oven processing is used to apply temperature and pressure to manufacture composite components.

- Quality: All aspects of the process of manufacturing are controlled and monitored and fully traceable.